Forklift Maintenance and Inspection: Essential for Safe Operation

Forklifts are very useful in many industries, but it’s important to keep them safe and operational through regular maintenance and inspection to prevent any accidents and keep everyone safe around the workplace. Read More

Importance of Forklift Maintenance: Performing maintenance on a forklift is related to scheduling routine checks to keep the forklifts in good working condition. Regular maintenance helps to identify and fix problems before they become serious issues. It includes tasks such as checking fluid levels, inspecting brakes, and examining tires. By maintaining forklifts properly, the risk of breakdowns and accidents decreases significantly. Key Tasks of Maintenance : Fluid Checks: Forklifts rely on various fluids like oil, hydraulic fluid, and coolant to operate smoothly. Regularly checking and topping up these fluids ensures that the forklift functions correctly and prevents damage to its components. Battery Maintenance: Electric forklifts require regular battery maintenance to ensure optimal performance. This includes checking battery water levels, cleaning terminals, and inspecting for signs of damage. Inspecting Brakes: Properly functioning brakes are crucial for safe forklift operation. Regular inspections help identify worn brake pads or other issues that could compromise braking performance. Tire Inspections: Forklift tires undergo significant wear and tear due to the heavy loads they carry. Regular inspections help detect tire damage or wear, reducing the risk of tire blowouts or accidents. Checking Safety Features: Forklifts are equipped with various safety features such as horns, lights, and seat belts. Regular checks ensure these features are in working order, enhancing overall safety. Forklift Safety Inspections: Regular inspection is like the forklifts’ thorough examination to ensure they’re safe to use. Inspections involve checking different components of the forklift to identify if any issues or potential hazards and fix them. Operators or trained maintenance personnel normally perform these inspections before each shift or at regular intervals. Inspections will help to detect problems early and prevent accidents from occurring caused by faulty equipment. Inspection Key Points: Visual Checks: Inspectors visually examine the forklift for any visible signs of damage, leaks, or wear. This includes looking for fluid leaks, damaged components, or loose parts. Functional Checks: Inspectors test various functions of the forklift to ensure they are working correctly. This includes testing the brakes, steering, horn, lights, and other safety features. Load Capacity Inspection: Ensuring that the forklift’s load capacity is higher than the load it is carrying is crucial for preventing accidents. Review Documentation: Review maintenance records and documentation to ensure that the forklift has been properly maintained and serviced according to manufacturer recommendations. Conclusion: Forklift maintenance and inspection are integral parts of ensuring safety in the workplace. Proper maintenance of forklifts and conducting regular inspections can prevent accidents, protect employees, create a safer working environment for everyone, and avoid costly downtime.

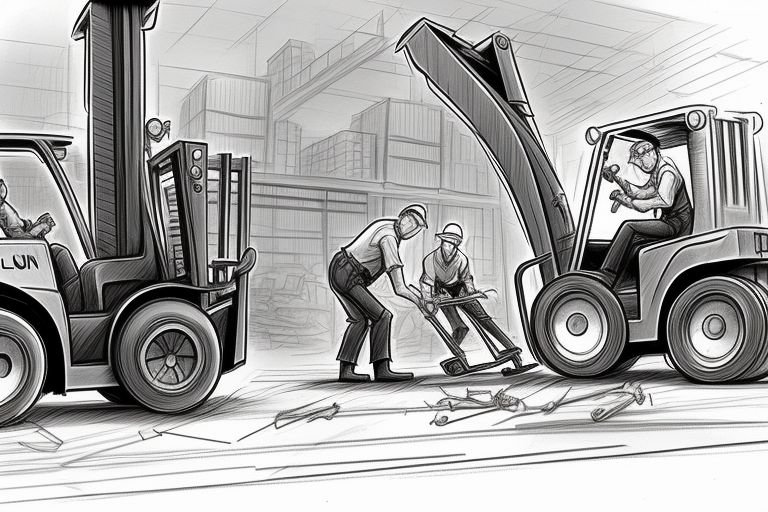

Common Forklift Accidents and How to Prevent Them

Forklifts are essential machinery in many industries, helping to move and manage heavy loads efficiently. However, they can be dangerous if not handled carefully. Accidents with forklifts can cause severe injuries, damage to property, and even death. Forklift accidents can happen for several reasons, and it’s essential to understand how to prevent them. Here are some common accidents and ways to avoid them:Read More

Forklift Overturns:

Forklifts can tip over if they’re driven too fast, make sharp turns, operate on uneven surfaces, or carry loads beyond their capacity. To prevent overturns:

a.Ensure operators are trained to use forklifts safely.

b.Follow speed limits and avoid sudden turns.

c.Regularly check the forklift’s condition to ensure stability.

d.Use counterweights and stay within load capacity limits.

Pedestrian Collisions:

When forklifts share space with pedestrians, collisions can occur, especially if pedestrians aren’t aware of forklift movements. To prevent these accidents:

a.Create separate walkways for pedestrians away from forklift paths.

b.Install mirrors and warning signs for better visibility.

c.Train forklift operators to be alert and use horns near pedestrians.

d.Encourage communication between forklift drivers and pedestrians.

Falling Loads:

Improperly stacked or unsecured loads can fall from forklifts, risking harm to nearby workers and goods. To prevent this:

a.Train operators on proper load handling techniques and securing loads.

b.Inspect loads for stability before moving them.

c.Avoid overloading and distribute the load evenly.

d.Use appropriate attachments for irregularly shaped loads.

Crushing Accidents:

Forklifts can accidentally crush workers or objects, especially in confined spaces or during loading and unloading. To prevent crushing accidents:

Establish clear protocols for safe loading and unloading.

Provide training on operating forklifts in tight spaces.

Install barriers to protect workers from collisions.

Regularly inspect for potential hazards.

Forklift Fires:

Forklifts powered by internal combustion engines can catch fire due to fuel leakage or electrical faults. To reduce fire risk:

a.Conduct routine maintenance checks.

b.Handle fuel safely and store it away from ignition sources.

c.Install fire suppression systems.

d.Train operators on responding to fires and evacuating safely.

Inadequate Training:

Lack of proper training for forklift operators increases the risk of accidents. To ensure operators are competent:

a.Provide comprehensive training programs.

b.Offer refresher courses regularly.

c.Require operators to obtain certification.

Ignoring Safety Guidelines:

Not following safety protocols raises the risk of accidents. Employers and operators must prioritize safety by:

a.Enforcing safety protocols strictly.

b.Promoting a safety-conscious culture.

c.Investigating accidents thoroughly to prevent future occurrences.

In conclusion, preventing forklift accidents requires training, careful operation, and adherence to safety measures. By addressing common risk factors and promoting safety, workplaces can reduce accidents and protect workers and property. Safety should always be the top priority when using forklifts.

Title: How to Ensure Safe Operation of Forklifts in the Workplace

Safety should be the primary concern in any workplace where forklifts are used. Forklifts are powerful machines designed to lift and move heavy loads, but they can also be dangerous if not operated correctly. Any workplace, it’s important to follow proper safety measures to prevent accidents and injuries. Here are some key steps to ensure the safe operation of forklifts in the workplace. Read More

Training and Certification: The first and most important step in ensuring safe forklift operation is to provide thorough training to all operators. Training programs should cover forklift controls, load handling, stability principles, and safety procedures. Operators should also learn about the specific hazards in their workplace. Additionally, operators must be certified to operate a forklift safely. Inspections and Maintenance: Regular inspections and maintenance are essential to keep forklifts in safe working condition. Before each use, operators should inspect the forklift for any signs of damage or malfunction. This includes checking the tires, brakes, steering, lights, horn, and hydraulic system. Any issues should be reported immediately and addressed by trained maintenance personnel. Routine maintenance schedules should also be established to ensure that forklifts receive proper servicing as recommended by the manufacturer. Loading and Handling: Proper loading and handling of loads are critical for maintaining stability and preventing accidents. Operators should adhere to the forklift’s load capacity and ensure that loads are stable and evenly distributed on the forks. It’s essential to avoid overloading the forklift or carrying loads that exceed the specified weight limits. Operators should be trained in safe lifting techniques, including how to stack loads securely and avoid obstacles in the workspace. Safe Operating Practices: Implementing safe operating practices is key to reducing the risk of accidents. Operators should always wear seat belts while operating the forklift and maintain a clear line of sight by keeping loads at a safe height. They should also observe speed limits and drive at a safe speed, especially when turning or navigating narrow aisles. It’s crucial to avoid abrupt stops, starts, or sharp turns that could cause the forklift to tip over. Operators should also be mindful of pedestrians and other vehicles in the workplace and use horns or warning signals when necessary. Storage and Housekeeping: Proper storage of materials and maintaining a clean work environment can contribute to forklift safety. Ensure that storage areas are organized, and aisles are clear of obstructions to prevent accidents. Hazardous materials should be stored according to safety regulations, and proper signage should be used to indicate potential hazards. Regular housekeeping practices, such as cleaning up spills and removing debris, can help prevent slips, trips, and falls that could lead to accidents involving forklifts. Emergency Procedures: Despite all precautions, emergencies can still occur. Therefore, it’s essential to have clear emergency procedures in place and ensure that all operators are trained to respond appropriately. This includes knowing how to safely evacuate the forklift in case of fire or other emergencies, as well as understanding how to use fire extinguishers and other emergency equipment. Regular drills and training sessions can help reinforce these procedures and ensure that everyone knows what to do in an emergency. Continuous Improvement and Feedback: Safety should be an ongoing process, with regular reviews and feedback mechanisms in place to identify areas for improvement. Encourage open communication between management, operators, and safety personnel to discuss any safety concerns or suggestions for improvement. Conduct regular safety inspections and audits to identify potential hazards and address them promptly. By continuously striving to improve safety practices, you can create a workplace environment where forklifts can be operated safely and efficiently In conclusion, ensuring the safe operation of forklifts in the workplace requires a comprehensive approach that includes proper training, regular inspections, safe operating practices, and clear emergency procedures. By prioritizing safety and implementing appropriate measures, you can minimize the risk of accidents and injuries associated with forklift operation, creating a safer work environment for everyone involved. Safety is everyone’s responsibility, and working together safely, we can prevent accidents and ensure a safer workplace for all.

10 Tips for Safe Forklift Operation in the Workplace

It’s important to operate a forklift safely to avoid accidents and injuries at work. Here are 10 tips that will help to do that:

Trained and Certified: Make sure all forklift operators have proper training and certification. They should know how to use the forklift safely and understand the workplace rules. Read More

Check the Forklift: Before you use it, look over the forklift for any damage or problems. Check things like the tires, brakes, and lights. If you find any issues, tell someone right away. Wear the Right Gear: Operators should wear the right gear, like a hard hat, safety shoes, and a vest that’s easy to see. This gear keeps them safe from possible dangers. Don’t Overload: Never put more weight on the forklift than it can handle. Putting too much weight on it could make it tip over and cause an accident. Secure Loads Well: When you lift or move things, make sure they’re tied down properly. If the load isn’t stable, it could move and hurt someone. Drive Safely: Stick to the speed limit and drive carefully, especially when turning or in busy areas. Going too fast makes accidents more likely. Keep a Clear View: Make sure you can see where you’re going. Use mirrors if you have them and always look ahead. Be careful at intersections and corners where you might not see well. Use the Horn and Lights: Use the horn to warn others when you’re coming. Keep the lights on if it’s dark so people can see you. Avoid Risky Moves: Don’t do anything risky, like turning sharply or stopping suddenly. Be careful on ramps or uneven ground to stay balanced. Follow the Rules: Obey all the rules at work, like staying in forklift lanes and giving pedestrians space. Be polite to others and watch out for them. If you follow these tips and stay careful, you’ll help keep everyone safe while using the forklift.

5 Safety tips for forklift operators

1.Always Wear a Seatbelt: Make sure to wear the seatbelt at all times when operating a forklift which will help protect you in the event of an accident.

2.Stay Alert: Always stay alert when operating a forklift, and paying attention to your surroundings, other workers, and any potential hazards. Read More

3.Keep a Safe Distance: Keep a safe distance from other workers and obstacles when operating a forklift. This will help reduce the risk of accidents or collisions. 4.Follow Speed Limits: Always follow the speed limits when operating a forklift. If you are driving too fast it can reduce your control over the forklift and increase the risk of accidents. 5.Properly park the Forklift: When not in use, make sure to properly park the forklift in a designated area, turn off the engine, lower the forks, and engage the hand/parking brake.